SHINE Project Case in Market

SHINE Project Case in Market

At Shine New Material, we take pride in our innovative solutions and successful collaborations. This page highlights some of our most impactful projects, demonstrating our expertise in advanced materials and our commitment to driving progress across various industries.

Each case study presented here showcases how our cutting-edge materials have helped our clients overcome challenges, improve product performance, and achieve their goals. From automotive lightweighting to next-generation electronics, these projects exemplify our dedication to pushing the boundaries of material science.

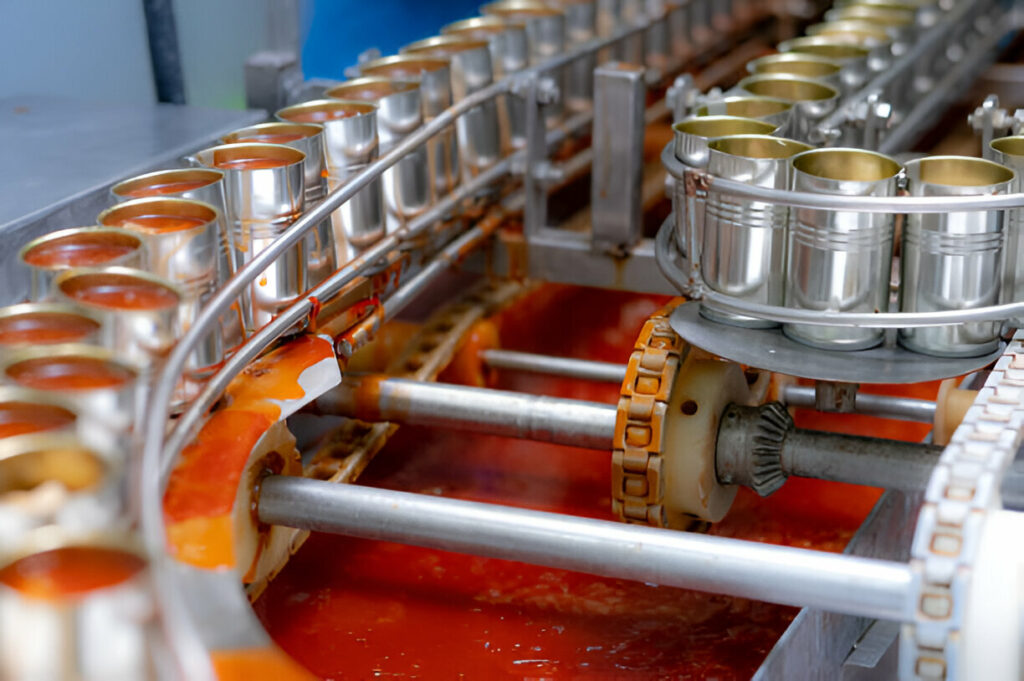

Golden Flavor Foods Co. ltd

Golden Flavor Foods Co. ltd is a medium-sized food company that produces a wide range of canned foods. Due to increasing market demands for food safety and shelf life, Golden Taste needed high quality, corrosion resistant packaging materials.

We worked with Golden Taste Foods to provide customized, high-quality tin-plated sheets and optimize the packaging design for their canned goods. By improving the corrosion resistance and sealing properties of the packaging material, it ensures a long shelf life for the food.

The new packaging solution helped Golden Flavor Foods reduce packaging costs by 20% and extend shelf life by 30%. The market response has been favorable and customer satisfaction has increased significantly.

Refreshing Beverage Co. ltd

Background:

Refreshing Beverage Co. ltd is a small beverage manufacturer committed to providing environmentally friendly and healthy beverages. The company wanted to enhance its brand image by adopting environmentally friendly and attractive packaging materials.

Process:

We provided Refreshing Beverages with sustainable, eco-friendly tinned sheets with an aesthetic design to make the products more attractive on the shelf. At the same time, we helped them optimize their production process to ensure that the packaging materials were environmentally friendly.

Results:

The new packaging not only enhanced the brand image, but also significantly improved customer satisfaction and increased market share by 15%.

Yali Cosmetics Co., Ltd.

Background:

Yali Cosmetics Co., Ltd. is a medium-sized cosmetic company dedicated to the high-end market. The company needed high-end and anti-corrosive packaging materials to match the positioning of its high-end products, and wanted to enhance the competitiveness of its products in the market.

Process:

We supplied high-quality tin-plated sheets with a high-end texture and designed packaging to meet the needs of the high-end market. By improving the corrosion resistance and texture of the packaging material, we were able to enhance the high-end image of the product.

Results:

The new packaging solution enabled Yali Cosmetics to significantly improve its competitiveness in the high-end market, strengthen its brand reputation, and increase sales by 20%.

Oasis Chemical Co. Ltd.

Background:

Oasis Chemical Co. Ltd. is a company specializing in the production of chemical products and needed corrosion-resistant, high-strength packaging materials to ensure the safe transportation and storage of its products.

Process:

We provided Oasis Chemical with high-strength tin-plated sheets and designed a leak-proof packaging structure to ensure that the chemical products would not leak or corrode during transportation and storage.

Results:

The new packaging solution reduced losses due to leakage and corrosion by 10% of the transportation risk, and the customer feedback was very satisfactory.

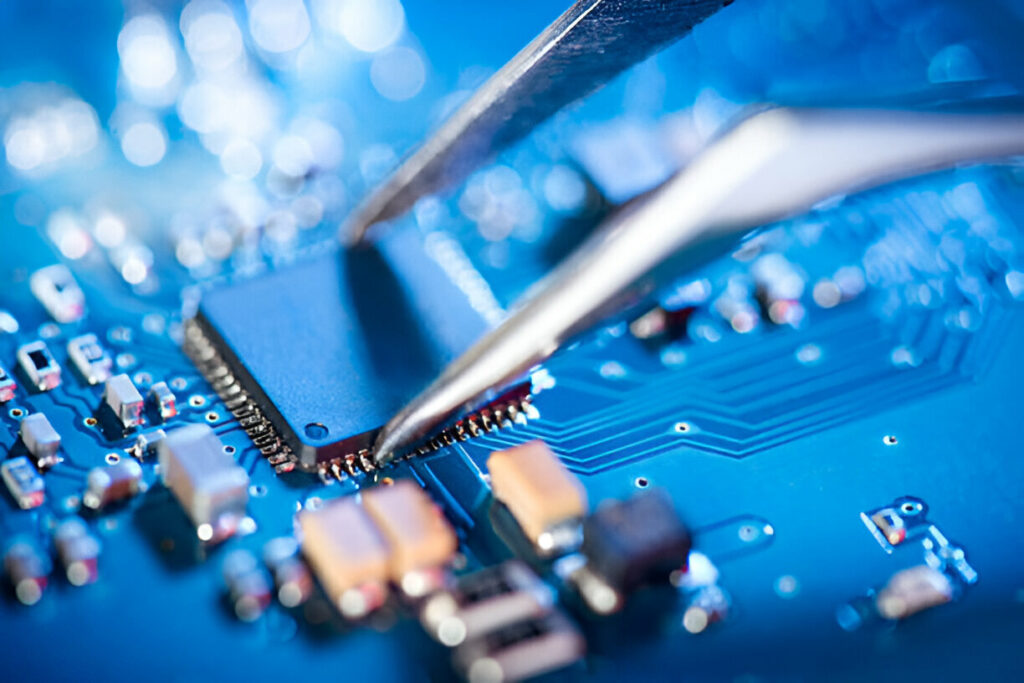

Zhixin Electronics Co., Ltd.

Background:

Zhixin Electronics Co., Ltd. is a manufacturer of high-precision electronic components and needs anti-static and moisture-proof packaging materials to protect its products during transportation and storage.

Process:

We supplied Chihshin Electronics with tin-plated sheets with anti-humidity and anti-static properties, and designed a specialized packaging structure to ensure that the electronic components would not be damaged during transportation and storage.

Results:

The new packaging solution improved the safety of electronic components, reduced product damage by 30%, and significantly increased customer satisfaction.